For Sale

When you click on links to various merchants on this site and make a purchase, this can result in this site earning a commission. Affiliate programs and affiliations include, but are not limited to, the eBay Partner Network.

:

$

Related Items:

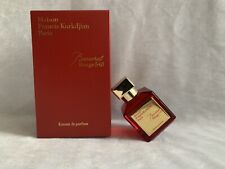

Maison Francis Kurkdjian Baccarat Rouge 540 Eau De Parfum 2.4 Oz FACTORY SEALED.

$99.98

Chanel Chance Eau Tendre Eau De Parfum Spray 3.4 Fl. Oz. Parfum for Women

$69.99

Borax 20 Mule Team 65 SAME DAY PRIORITY SHIP 1 gram 1oz ounce 1 pound 100lb BULK

$359.99