Hi Mike, thank you for your comment, but I think you do not understand the concept. Perhaps I haven't explained it well.

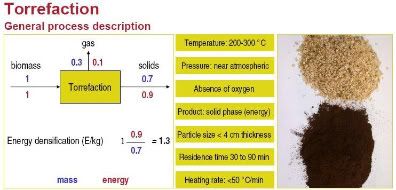

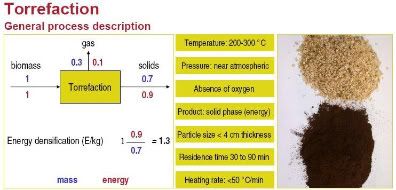

The goal is to torrefy biomass. You do this by heating it to 200-300 °C, in separate stages and in a low-oxygen environment. The result of this roasting process is a dry biomass that is easily crumbled into a powder.

This powder, or the small granular pieces will then, on-site, be pelletized (just like you would pelletize non-torrefied biomass).

The pellets can then be shipped over much larger distances than ordinary biomass pellets. And they can be used in coal-fired power stations.

Currently, torrefaction relies on heat that is most often obtained from a fossil fuel source. I want to skip that step, and use heat from solar concentrators.

You know those solar cookers and solar ovens, right? You can cook biomass in these. But the temperatures obtained by these low-cost, simple solar cookers is not high enough (150-200 °C max). Solar concentrators such as the ones used in CSP plants can reach much higher temperatures.

So I want to use these concentrators, heat a thermal fluid (like oil) and use this heat to roast the biomass. Torrefaction is roasting. It's not pyrolysis. The only byproduct is a low-energy gas, no tars or liquids. You can drive off the gas, and reuse it.

See the short overview of the process.