9 November 2010

Nanogenerator powers conventional electronics

by Kate Melville

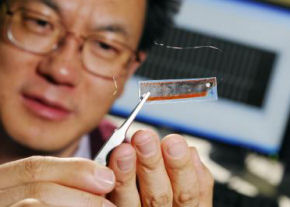

Electronic gadgets that don't require charging are a step closer after the successful demonstration of a nanoscale generator that produces enough electricity from mechanical movement to power a LCD display. Device inventor Zhong Lin Wang, from Georgia Tech, explained that the mechanical energy needed to drive the generator could come from a heartbeat, the pounding of a shoe on a footpath, the rustling of a shirt, or the vibration of a heavy machine.

Electronic gadgets that don't require charging are a step closer after the successful demonstration of a nanoscale generator that produces enough electricity from mechanical movement to power a LCD display. Device inventor Zhong Lin Wang, from Georgia Tech, explained that the mechanical energy needed to drive the generator could come from a heartbeat, the pounding of a shoe on a footpath, the rustling of a shirt, or the vibration of a heavy machine.

Wang's nanogenerators rely on the piezoelectric effect seen in crystalline materials such as zinc oxide, in which an electric charge potential is created when structures made from the material are flexed or compressed. By capturing and combining the charges from millions of these nanoscale zinc oxide wires, Wang and his research team can produce as much as three volts at currents of up to 300 nanoamps.

"By simplifying our design, making it more robust and integrating the contributions from many more nanowires, we have successfully boosted the output of our nanogenerator enough to drive devices such as commercial liquid-crystal displays, light-emitting diodes and laser diodes," said Wang. "If we can sustain this rate of improvement, we will reach some true applications in healthcare devices, personal electronics, or environmental monitoring."

The earliest zinc oxide nanogenerators used arrays of nanowires grown on a rigid substrate and topped with a metal electrode. Later versions embedded both ends of the nanowires in polymer and produced power by simple flexing. Regardless of the configuration, the devices required careful "growth" of the nanowire arrays and painstaking assembly.

The latest device, however, uses a much simpler fabrication technique. First, the research team grew arrays of a new type of nanowire that has a conical shape. These wires were cut from their growth substrate and placed into an alcohol solution.

The solution containing the nanowires was then dripped onto a thin metal electrode and a sheet of flexible polymer film. After the alcohol was allowed to dry, another layer was created. Multiple nanowire/polymer layers were built up into a kind of composite, using a process that Wang believes could be scaled up to industrial production.

When flexed, these nanowire sandwiches - which are about two centimeters by 1.5 centimeters - generated enough power to drive a commercial display borrowed from a pocket calculator.

While even the current nanogenerator output remains below the level required for such devices as iPods or cardiac pacemakers, Wang believes those levels will be reached within three to five years. The current nanogenerator, he notes, is nearly 100 times more powerful than what his group had developed just a year ago.

"From when we got started in 2005 until today, we have dramatically improved the output of our nanogenerators," Wang noted. "We are within the range of what's needed. If we can drive these small components, I believe we will be able to power small systems in the near future. In the next five years, I hope to see this move into application."

Related:

Battery built from GM viruses

Acoustic fabric functions as speaker and microphone

Nanotronics within reach with creation of molecule-sized diode

"Spin battery" provides novel electrical storage

Wireless Power Transfer Revisited

Source: Georgia Institute of Technology Research News